Introduction

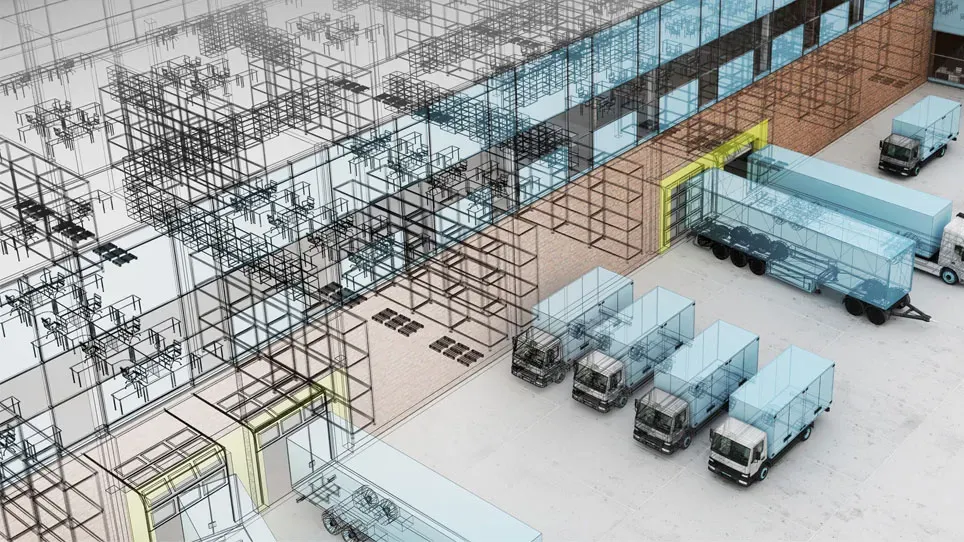

Warehouses play a critical role in matching product demand with supply across different echelons in the supply chain. No supply chain design and management is adequate without deciding the location, design and management of warehouses. Today, warehouses operate not only as centres for storage but also as centres for value-addition. Several warehouses have assembly, packaging and repair operations within their premises. Warehouse decision models are crucial for an organisation’s profitability. Existing research shows that understanding warehouse design and management principles can play a pivotal role in improving the efficiency of operations; reducing employee fatigue and turnover; and improving customer service levels. New warehouse automation systems can help increase operational flexibility and cater growing customer expectations.

The research agenda in warehousing includes optimisation-based decision models for addressing strategic, tactical and operational warehouse problems, performance analysis of both manual and automated warehouse systems (including robotised systems) using stochastic models, new warehouse design principles, behavioural operations management in warehouses, tools for managing complex e-commerce warehouse operations such as managing returns, cost models for selection of automated material handling solutions, warehouse safety and security, warehousing contracts, etc. Recently, several conferences have been organised around these themes such as the International Material Handling Research Colloquium, June 2016, in Germany, the tracks at the annual EURO and Informs conferences or at the 15th IFAC Symposium on Information Control Problems in Manufacturing, Ottawa, Canada (incom2015.org). Over time (the journal celebrates its 55th volume anniversary this year), the International Journal of Production Research has proven to be one of the key outlets for promoting research in warehouse design and management.

A literature search in the International Journal of Production Research since 1997 (using Google Scholar with the Keywords ‘Warehousing’ and any of the key words ‘order picking’, ‘batching’, ‘zoning’, ‘layout’, ‘routing’, ‘storage’, ‘retrieval’, ‘technology’, or ‘design’) yields over 100 papers. The relevant papers with most citations/year are listed in Table , whereas the count of published articles in International Journal of Production Research related to warehousing area is shown in Figure . An increasing trend in the publication count suggests that there is a growing interest of the researchers in warehousing.

Papers in the special issue

In their paper A Hierarchical Approach to Warehouse Design, Timothy Sprock, Anike Murrenhoff and Leon F. McGinnis propose a hierarchical design decision support methodology for warehouses, based on decomposing the design problem into a set of subproblems and using a formal model of the system to integrate the solutions to these subproblems. The methodology enables a thorough search of the design space and the identification of candidate designs for consideration by the designer. The design methodology is demonstrated with an example of designing a forward pick area.

Christoph H. Glock, Eric H. Grosse, Ralf M. Elbert and Torsten Franzke study maverick order picking behaviour, or workplace deviance (either in a positive or negative sense), in their paper Maverick picking: The Impact of Modifications in Work Schedules on Manual Order Picking Processes. Maverick picking can influence the performance of the picking process. Their paper studies its causes, its forms of appearance and the potential impact on performance. Their results, based on a multi-case study, support the proposition that maverick picking is a major determinant of order picking performance.

Thomas Chabot, Rahma Lahyani, Leandro C. Coelho and Jacques Renaud study order picking routing in their paper Order Picking Problems under Weight, Fragility and Category Constraints. They include product-specific constraints that are often neglected, such as weight, fragility and category constraints. They present four heuristic methods, including extensions of the classical largest gap, midpoint and S-shape heuristics, as well an adaptive large neighbourhood search algorithm. They show their ALNS method outperforms the other heuristics and that it has tight gaps with two mathematical models.

To meet strict delivery deadlines in a volatile demand environment such as e-commerce, a good plan of worker requirements is crucial. Teun van Gils, Katrien Ramaekers, An Caris and Mario Cools propose time series-based models to accurately forecast the daily number of order lines in a warehouse, in their paper The Use of Time Series Forecasting in Zone Order Picking Systems to Predict Order Pickers’ Workload. Using a real case study, they show that such information can be very useful to estimate the number of order pickers and also assign them to pick zones.

E-commerce warehouse operations have to cope with large fluctuations in customer order volumes and a large proportion of product returns. Hence, optimal policies for traditional manual warehouses may not be suitable for e-commerce warehouses. To address this gap, Albert H. Schrotenboer, Susanne Wruck, Kees Jan Roodbergen, Marjolein Veenstra and Arjan S. Dijkstra study the optimal pick routes in their paper titled Order Picker Routing with Product Returns and Interaction Delays using a hybrid genetic algorithm. The algorithm determines routes for simultaneous pickup of products in response to consumers’ orders and delivery of returned products to storage locations.

Order picker discomfort is of significant concern in manual order picking process and is often ignored while identifying the best item storage location. José A. Larco Martinelli, René B.M. De Koster, Kees Jan Roodbergen and Jan Dul attempt to address this gap in their paper titled Managing Warehouse Efficiency and Worker Discomfort through Enhanced Storage Assignment Decisions. They propose an elegant two-stage solution methodology to address these dual objectives. In the first stage, they build data-driven empirical models for estimating cycle times and workers’ discomfort. In the second stage, the empirical models are adopted to formulate a bi-objective assignment problem for assigning products to storage locations. The model is tested for two real facilities.

Puzzle-based storage systems are a new type of automated storage systems that allow storage of unit loads in a rack on a very small footprint with individual accessibility of all loads. Such systems are already adopted for dense parking, dense storage in vessels and new warehousing applications are at the horizon. Masoud Mirzaei, René B.M. De Koster and Nima Zaerpour develop an optimal method to retrieve two loads simultaneously in their paper titled Modelling Load Retrievals in Puzzle-Based Storage Systems. They also develop a heuristic approach for efficiently retrieving more than two loads. Such algorithms hold promise for practice because they can reduce the travel time by more than 15%.

Optimising space utilisation is one of the main goals in warehouse design and operation. While block-stack storage is an inexpensive storage system widely used in manufacturing operations for storing pallets, the optimal storage layout dimensions under a finite production rate are still unknown. In their paper titled Optimising Space Utilisation in Block Stacking Warehouses, Shahab Derhami, Jeffrey S. Smith and Kevin R. Gue propose mathematical models to obtain the optimal lane depth. They use a simulation model to analyse the layout performance with stochastic input parameters.

Powered by Froala Editor

Related Insights & Articles

July 14, 2025

At vero eos et accusamus et iusto odio dignissimos ducimus qui blanditiis praesentium

At vero eos et accusamus et iusto odio dignissimos ducimus qui blanditiis praesentium voluptatum deleniti atque corrupti quos dolores et quas molestias excepturi sint occaecati cupiditate non provident, similique sunt in culpa qui officia deserunt mollitia animi, id est laborum et dolorum fuga. Et harum quidem rerum facilis est et expedita distinctio. Nam libero tempore, cum soluta nobis est eligendi optio cumque nihil impedit quo minus id quod maxime placeat facere possimus, omnis voluptas assumenda est, omnis dolor repellendus. Temporibus autem quibusdam et aut officiis debitis aut rerum necessitatibus saepe eveniet ut et voluptates repudiandae sint et molestiae non recusandae. Itaque earum rerum hic tenetur a sapiente delectus, ut aut reiciendis voluptatibus maiores alias consequatur aut perferendis doloribus asperiores repellat.

Powered by Froala Editor

July 18, 2025

Global E-Commerce Trends Reshaping the Supply Chain in 2025

Introduction

E-commerce continues to grow at an unprecedented rate, influencing how products are manufactured, stored, shipped, and delivered. As consumers expect faster, cheaper, and more convenient services, supply chains must evolve to keep up. The trends shaping e-commerce today are directly impacting how warehouses and logistics operations function.

1. Rise of Hyperlocal Fulfillment

To reduce delivery times, companies are building micro-fulfillment centers close to major urban areas. These small, tech-enabled warehouses reduce the last-mile burden and enable same-day or even 1-hour deliveries.

2. Omnichannel Supply Chains

Retailers now sell through websites, apps, marketplaces, and physical stores — all integrated into a single inventory and fulfillment system. This omnichannel model requires real-time visibility across all platforms, and flexible logistics that can respond to orders from anywhere.

3. Reverse Logistics Growth

As online returns grow (especially in fashion and electronics), the demand for efficient reverse logistics is rising. Brands are investing in return hubs, automated inspection systems, and resale programs.

4. Eco-Conscious Consumer Demands

Customers are increasingly favoring brands that offer green delivery, minimal packaging, and carbon-neutral operations. This is pushing logistics firms to adopt electric fleets and route optimization algorithms.

5. Personalization Through Data

Data analytics and AI allow for personalized delivery preferences, predictive shipping (based on past orders), and even dynamic packaging — helping improve both speed and customer satisfaction.

Conclusion

E-commerce isn’t just transforming online shopping — it’s redefining global supply chains. Warehouses and logistics providers that adapt to these new trends will gain a competitive edge and remain relevant in the fast-moving digital economy.

Powered by Froala Editor

July 18, 2025

Top 5 Warehousing and Logistics Market Trends to Watch in 2025

Introduction

The warehousing and logistics sector is experiencing a surge in innovation. Driven by demand for faster delivery, higher efficiency, and sustainability, 2025 brings a new wave of transformation. Businesses that understand these trends can stay ahead in a competitive market.

1. Warehousing-as-a-Service (WaaS)

Just like cloud computing, on-demand warehousing allows businesses to rent space only when needed. Startups and SMEs are using WaaS platforms to scale operations without heavy investment.

2. Rise of Urban Logistics Hubs

Due to urbanization, the focus is shifting toward small-scale warehouses in cities to support last-mile delivery. This trend helps reduce transit time and supports instant delivery models like food and grocery.

3. Autonomous Material Handling

Forklifts, pallet movers, and conveyor belts are becoming smarter. AMRs (Autonomous Mobile Robots) and AGVs (Automated Guided Vehicles) are becoming mainstream in large and medium warehouses.

4. Real-Time Data & Predictive Logistics

With IoT sensors and AI systems, warehouses can now predict inventory needs, identify maintenance issues early, and track shipments at every stage — offering full visibility.

5. Labor Shortage Driving Tech Adoption

The global shortage of warehouse workers is forcing companies to invest in automation, wearable tech (like smart glasses), and robotics to maintain performance and output.

Conclusion

The warehousing and logistics market is no longer just about space — it’s about agility, speed, and intelligence. These trends show where the industry is headed and how businesses can evolve to meet new expectations.

Powered by Froala Editor